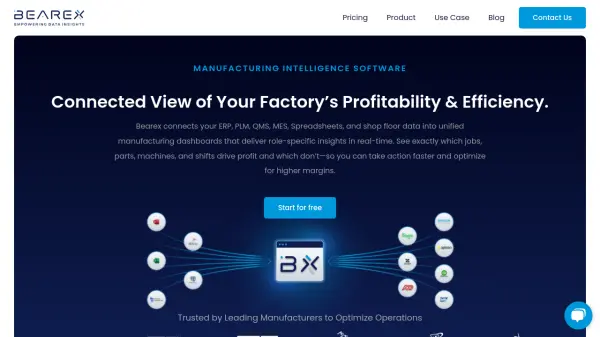

What is Bearex?

Bearex provides an advanced manufacturing intelligence software platform designed to integrate ERP, PLM, QMS, MES, spreadsheets, and shop floor data into unified dashboards for actionable, real-time insights. It delivers role-specific dashboards that allow manufacturers to pinpoint which jobs, parts, machines, and shifts drive profits and efficiency, empowering faster decision-making and operational optimization.

The platform streamlines production management by offering live shop floor monitoring, quality management analytics, financial performance insights, and labor efficiency tracking. With robust data integration capabilities and expert consulting support, Bearex enables manufacturers to reduce downtime, optimize production schedules, and achieve continuous process improvement without the need for extensive IT infrastructure or dedicated data analysts.

Features

- Unified Data Integration: Connects ERP, PLM, QMS, MES, spreadsheets, and shop floor data

- Real-Time Dashboards: Delivers live, role-specific manufacturing insights

- Production Analytics: Enables root-cause and manufacturing performance analysis

- Financial Insights: Provides profitability tracking and cost optimization

- Labor and Shift Monitoring: Tracks employee and shift-level efficiency metrics

- Automated Alerts & Reports: Sends automated notifications and updates

- Custom Data Mapping: Supports personalized dashboards for unique operational needs

- Seamless Deployment: Go live in as little as three weeks without specialist IT support

- Expert Consulting: Includes ongoing support and training after deployment

- Secure Data Handling: Employs security measures like whitelisting, port masking, and multi-factor authentication

Use Cases

- Integrating and visualizing manufacturing data from multiple business systems

- Tracking real-time production performance for plant managers

- Performing root-cause analysis on recurring production issues

- Monitoring shift efficiency and employee performance

- Analyzing standard production costs and profitability by client or department

- Optimizing production scheduling and resource allocation

- Validating return on investment with centralized data insights

- Supporting continuous improvement initiatives with actionable intelligence

FAQs

-

What am I really getting with Bearex?

Bearex aggregates disparate manufacturing data sources, delivering real-time dashboards that summarize key metrics such as sales, efficiencies, productivity, gross margins, and more, accessible in one unified platform. -

How do we get started with Bearex?

Implementation begins with a virtual introduction call, followed by an in-depth discovery phase to identify requirements, connect data sources, and customize dashboards before going live. -

What is the process for deploying Bearex?

Deployment involves connecting identified data sources, customizing dashboards during discovery, and ensuring all dashboards are calibrated with substantiated data before going live. -

How does Bearex differ from standalone BI tools?

Unlike generic business intelligence software, Bearex combines data science with manufacturing and financial expertise, delivering a turnkey solution tailored to manufacturing environments without the need for a full-time data analyst. -

How does Bearex ensure data security?

Bearex utilizes security measures such as IP whitelisting, port masking, read-only database access, multi-factor authentication, and careful database loading to protect client data.

Related Queries

Helpful for people in the following professions

Bearex Uptime Monitor

Average Uptime

99.85%

Average Response Time

654 ms

Featured Tools

Join Our Newsletter

Stay updated with the latest AI tools, news, and offers by subscribing to our weekly newsletter.